Many businesses (about one in three) store hazardous chemicals on-site – restaurants, cleaning businesses, construction, gardening, hardware stores, fuel stations, and painters, to name a few. These chemicals are essential business tools and assets, but, they can and do represent a significant health and safety risk to employees who use or work near these dangerous substances.

WorkSafe reports that an estimated 600 to 900 deaths, and 30,000 cases of serious ill-health, arise from exposure to hazardous chemicals each year. And while manufacturers and suppliers are responsible for the secure packaging and transport of chemical products, the employer is liable for the safe use and storage of these substances in a workplace. You must take all reasonable steps to ensure your workers know how to handle and keep hazardous chemicals safely to avoid harm or hefty penalties. In February 2021, the Ministry for Primary Industries (MPI) was fined $30,000 for failing to adequately protect workers from exposure to a sodium hydroxide-based cleaner called X-Clean DOO AWAY.

Managing chemical risk in the workplace – a brief overview

The three primary responsibilities employers have in managing chemical risk are to:

- Create a risk register or inventory;

- Have Safety Data Sheets available for every hazardous substance; and

- Assess and manage the risks associated with a chemical substance including its storage and use.

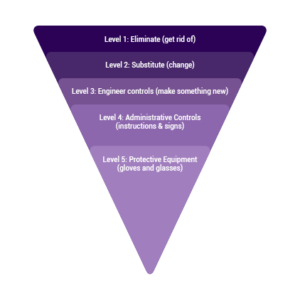

You can manage the risks of injury and ill-health through exposure or immediate harm (such as through explosions or fire) via the hierarchy of controls. If you’re unfamiliar with the hierarchy of control model, we explain it in detail in this Health & Safety eBook.

Hierarchy of controls

Storing hazardous chemicals in the workplace

There are three fundamental principles for safe storage of hazardous chemicals in the workplace. These are: store only what you need; avoid storing reactive chemicals together; and ensure you have chemicals stored in the right type of container with a clear and correct label.

The requirements for the safe storage of hazardous chemicals also apply to used and empty containers; these left-over vessels can contain residue that may present a higher risk of fire or explosion due to the greater volatility of their contents.

Recent changes to health and safety requirements for the storage of hazardous chemicals

Recently, two regulatory changes have passed that will affect administrative compliance for businesses that store or handle chemical hazards:

1. Location compliance certificate

You may require a location compliance certificate if you store explosive, flammable, oxidising, toxic or corrosive substances, and, the quantity you hold exceeds the thresholds defined in the Health and Safety at Work (Hazardous Substances) Regulations 2017.

For example: if you have more than 100 kilograms of LPG, more than 50 litres of petrol, or more than 250 litres of 60 per cent nitric acid (in storage) in a single location, you will need a location compliance certificate. Without this certificate, you’ll be storing these quantities unlawfully (and unsafely) on-site.

WorkSafe has an online calculator to assist with knowing (and making sure you don’t exceed) your non-certifiable limits.

You should apply for a location compliance certificate at least 30 days before you intend to set up your hazardous storage location.

Only a compliance certifier can issue your business with a location compliance certificate. WorkSafe keeps a register of certifiers that you can search to find someone authorised to issue these certificates under the Health and Safety at Work (Hazardous Substances) Regulations 2017.

Length of certification will vary depending on the type of chemical substance

The table below shows the length of time that a location compliance certificate is valid according to the type of hazardous chemical:

| Hazardous chemical | How long before you must renew the location compliance certificate? |

| Flammable and oxidising substances |

One year. However, you can apply to WorkSafe to extend this to three years if you meet certain requirements.

|

|

Toxic and corrosive substances, or less than 300kg LPG

|

Three years. |

Notifying WorkSafe of a new location for hazardous chemicals

You must notify WorkSafe online at least 30 working days before you commission a new location to store a dangerous compound.

2. New classification system

On 30 April 2021, a new classification system was introduced: The Hazardous Substances and New Organisms Act 1996 (HSNO). The HSNO established a new system for New Zealand businesses that aligns with international standards. This new system is called the “Globally Harmonised System (GHS 7)”; the “7” stands for the seventh revised edition. Over 50 countries use the GHS including, all New Zealand’s major trading partners.

From 30 April 2021, importers, manufacturers, and suppliers have up to four years to update all labelling, safety data sheets and packaging for hazardous substances. If a chemical has an individual approval issued after 30 April, it must comply immediately with the new classification system. All approvals issued before 30 April have a four-year transitional period until 30 April 2025. HSNO approval numbers have not changed.

For more information, you can visit these Environmental Protection Authorities webpages on hazard classification systems and individual hazardous substance approvals.

To complicate things further, regulations issued under the HSWA will continue to refer to the existing HSNO classification system; this means there’s no change to work requirements under the 2017 Hazardous Substances Regulations and 2016 Major Hazard Facilities regulations.

Because these two systems co-exist and could result in some confusion, the EPA has produced a correlation table that you can reference for clarity.

Four years might seem like a luxurious timeframe to get your hazardous chemical compliance in order. But keep in mind that many factors outside your control could cause delay and result in a breach of health and safety compliance. The best practice advice is to start early and make the necessary administrative changes as soon as possible to ensure you meet the regulatory deadline.

If this article has raised any questions or concerns or you’d like to learn more about how we can help your business, please reach out to our workplace relations experts via our 24/7 HR Advice Line.